Disciplines

Process Engineering

Volans Design Hub consists of experts and licensed process engineers for the development, design and implementation of modern technical and technological solutions in the field of environmental protection, including:

•wastewater treatment plants

•drinking water preparation

•waste gas treatment

•solid waste management

Given the complexity of technological processes that involve physico-chemical and biological processes, and the rapid development and sophistication of process equipment used in the environmental industry, process engineers have extensive experience and knowledge how to select and set the process flow at a highly professional level and to professionally supervise the implementation, management and optimization of plant operation. This way, the company provides professional support in all phases of plant construction:

•design

•commissioning

•process control and optimization

The main activities of process engineers include:

•preparation of studies

•expertise and technical documentation

•preparation of accompanying budgets and technical specifications

•assessment of investment and operating costs of the plant;

•coordination with other professions during the elaboration of the process solution that was set

•organization and management of technical documentation

•providing professional support during the period of works

•implementation and commissioning of designed plants

•testing, work optimization

•maintenance of process systems and technological equipment

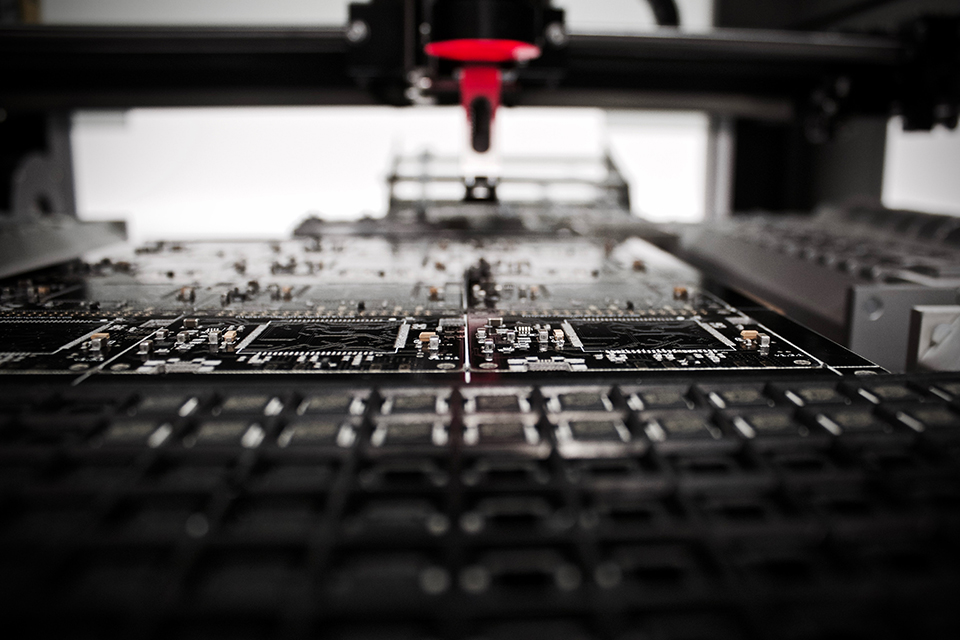

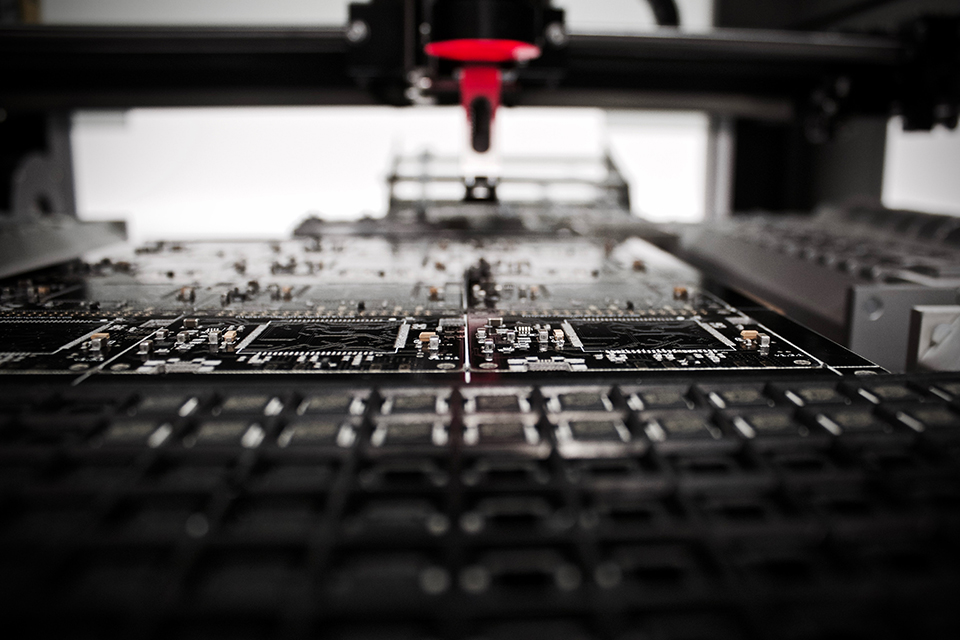

Mechanical Engineering

Within the company, a large number of experts and licensed mechanical engineers successfully apply extensive theoretical knowledge of different sciences with the use of design and mathematical methods, both in the development of process solutions that are set in the projects in the field of environmental protection and in design of mechanical structures and installation in other industries. The high level of professional ethics and expertise of engineers is successfully applied in:

•implementation of projects

•supervision in the installation of equipment

•commissioning

•testing

•performance optimization and maintenance

The main activities of mechanical engineers include:

•preparation of studies, expertise and technical documentation

•preparation of accompanying budgets and technical specifications

•preparation of budget estimates and estimates of investments in the plant construction

•preparation of budget estimates and estimates of investments in the plant construction

•organization and management of technical documentation

•supervision over the execution of works and commissioning of designed plants

•testing

•optimization of operation and maintenance of mechanical and hydro-mechanical equipment in designed process systems

In order to create projects of high accuracy and quality, mechanical engineers are trained to create projects using modern IT programs including CAD, Water CAD and Plant 3D, which allow them quickly and easily modification of projects.

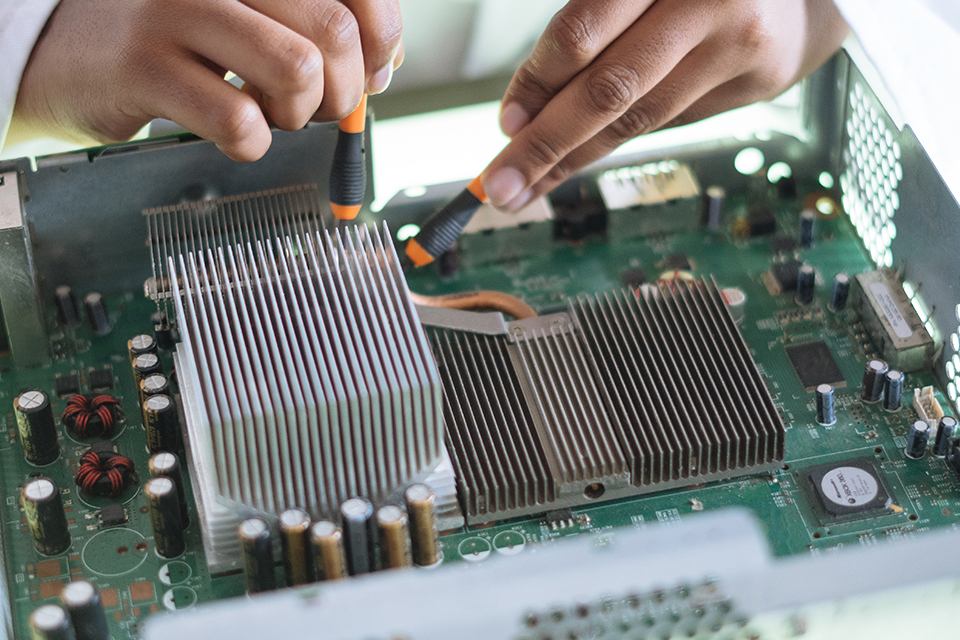

Electrical Engineering

Our electrical engineers work successfully in the field of energy, electric motor drive, automatic control, telecommunication and signal installations.

The main activities of electrical engineers include:

•preparation of technical documentation through all phases of design, from concept to execution

•preparation of all accompanying calculations, detailed specifications, graphic details and power and control diagrams

In addition to the preparation of technical documentation, electrical engineers can also provide services in the field of technical control of projects, design supervision, as well as the execution of all types of electrical work.

In the field of electrical work, the company can offer all the activities that occur during the construction, which are:

•selection of appropriate electrical equipment

•elaboration of the process solution that is set

•development of a control management philosophy

•parameterization and adjustment of measuring and regulating equipment, frequency regulators and other devices

•development of examination protocols

•coordination with other professions during the execution of works

After the completion of construction activities and commissioning of the plant, the company can offer complete management of regular monthly and annual servicing of equipment, which includes activities of regular inspection of all electrical equipment, checking the condition and status of all devices and measuring equipment with reports and proposals for work optimization.

Automation

Volans Design Hub is qualified to deliver solutions in the field of process control and automation.

The designed automation systems are based on DCS systems, PLC controllers and SCADA software.

We also select and, if necessary, deliver and put into operation complete measuring and regulating equipment, as well as equipment for detection and signaling.

Hydraulic Engineering

For the last 20 years, our engineers have been successfully solving problems in the areas of:

•preparation of drinking water

•municipal wastewater treatment plants

•industrial plants for wastewater treatment from technological processes

•industrial plants for wastewater treatment from technological processes

•industrial pipelines - transport of technical fluids

•public infrastructure

•pumping stations and pipelines for irrigation purposes

Construction and Architecture

Our team provides design and engineering services in the field of:

•architecture

•planning and urbanism

•structural and civil design

•MEP

Energy Efficiency

Although energy losses cannot be reduced to zero, they can be reduced in different ways using different techniques and with a careful or efficient approach energy can be consumed in optimal.

When used in an inappropriate manner, which means that there is a difference between the amount of energy supplied and the amount of energy required, this leads to wastage and thus to financial loss.

Inefficient use of energy is mostly the result of poor design, inadequate operating characteristics of the process and poor maintenance.

Our team of experts (architects, HVAC and electrical engineers) is fully trained and with the necessary certificates to deal with any kind of "Energy efficiency" challenge.

We are able to produce EE elaborates as well as Energy passports for all types of facilities.

Saving energy through energy efficiency improvements can cost less than generating, transmitting, and distributing energy from power plants, and provides multiple economic and environmental benefits.

During development of designs our team of engineers trying to achieve maximum energy efficiency in future work of the plants, some of the possibilities are as follows:

•Optimization of the solution for the selection of pumps and other motor consumers

•Installing smart measuring devices, developing control systems for the optimal operation

•Maximizing automatic operation with properly planned and integrated PLC and SCADA system, these solutions can provide many benefits, freeing operators to perform other duties

•Continuous monitoring and trending of various processes and equipment can reveal periods when energy usage can be reduced or peak energy loads can be saved

Conveyor and Bulk Material

Our team has many years of experience in the field of documentation of Conceptual Solution, Conceptual Design, Building Permit Project and Detailed Design for:

•civil design

•mechanical design

•electrical design